Your Consulting Resource from Development to Launch

At Canyon Labs, we want to be more than just a test laboratory. We want to support your project throughout the full development cycle and into production by leveraging our team’s extensive technical background.

Our consultants provide a wide range of services to compliment our compliance testing. This includes regulatory & quality, packaging engineering, sterilization validations, biocompatibility risk assessments, and more.

By providing consulting services, Canyon Labs can truly be your one-stop-shop to support your submission and launch.

Regulatory Consulting

Navigating the complex world of regulations can be challenging. Let our team of experts guide your next submission to success. With extensive experience in both U.S. and international markets, as well as a deep understanding of a wide range of device and drug types, we have the expertise you can rely on to get the results you need.

- 510(k) & PMA Submission

- Pre-Submission Meetings & Preparation

- FDA Response Support

- Internal Audits

- Standardized Testing Plan

- Quality Management Systems

- Documentation Gap Analysis

- Risk Management Support

- Sample Size Selection

Packaging Consulting

Your product is only as good as it’s package. Our team of medical and pharmaceutical packaging engineers can serve as your personal experts to handle anything from design to process implementation. Let us help speed up your next packaging project.

- ISO 11607 Guidance

- Sterile Packaging Design & Development

- Cold Chain Packaging Design & Development

- Custom Thermal Conditioning Profiles

- Validation Protocols & Reports

- Process Validation (IQ, OQ, PQ)

- Equipment Selection & Procurement

- Test Method Validation

- Worst-Case Packaging Justifications

- Sample Size Selection

- Failure Root Cause

- Onsite Training

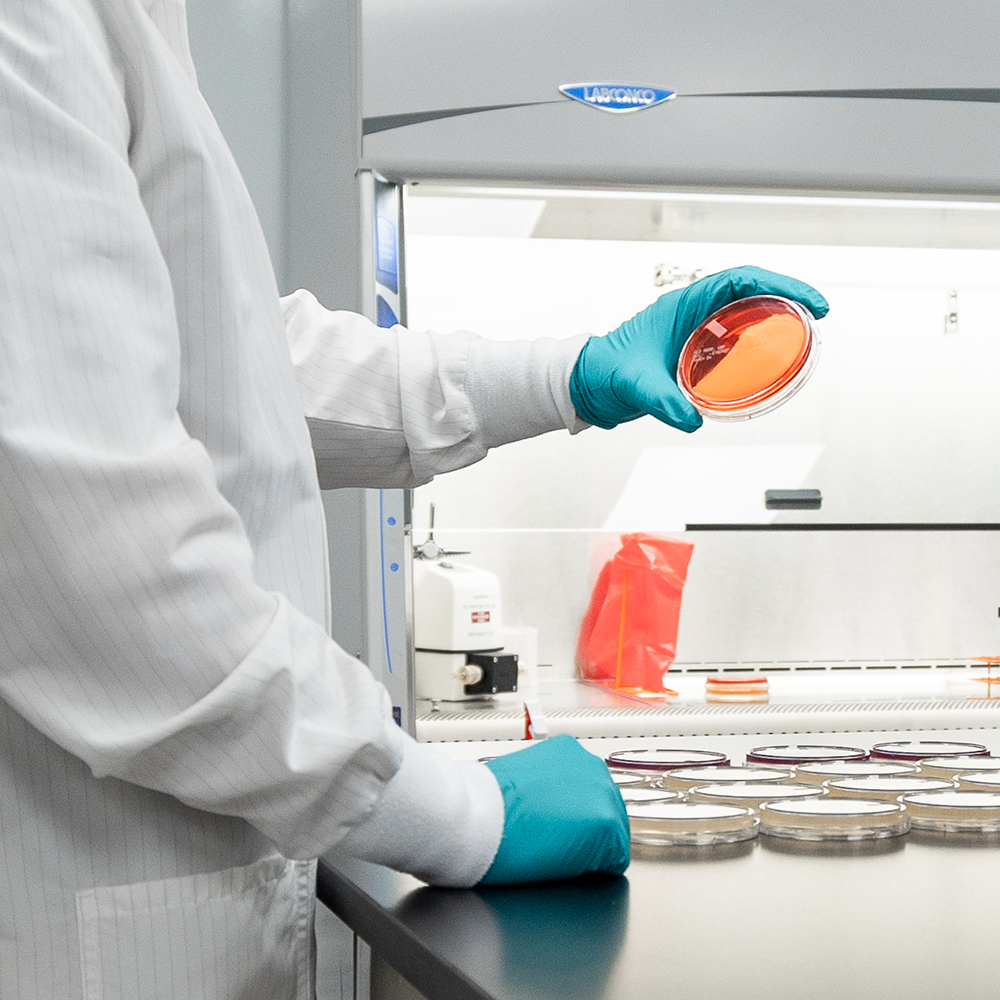

Sterilization Consulting

Developing an effective sterilization process is a critical part of every sterile medical device and pharmaceutical product. Each process must by validated to ensure your product remains sterile throughout its lifecycle and is safe for patient use. Our team of experts and partners can help guide you from start to finish.

- Ethylene Oxide (EO) Single Batch Release

- Ethylene Oxide (EO) Validation

- Comparative Resistence Studies

- Process Challenge Device (PCD) Development

- Gamma / E-Beam VDmax 25, Method 1, Method 2

- Gamma / E-Beam VDmax 25, Method 1, Method 2

- Steam Sterilization Dry Time Validation

- Steam Sterilization Thermal Profile

- Validation Protocols & Reports

- Modality Selection Support

- Sterlizer Selection & Coordination

- Product Family Justifications

- Alternative Modalities

- R&D Sterilization Runs

Toxicology

Biocompatibility is one of the crucial parts of the product development process, but it also the most misunderstood. Canyon Labs has a team of board-certified toxicologists to help you determine the level of biocompatibility testing is right for your product and evaluate the toxicological impact of test results.

- ISO 10993 Guidance & Gap Assessments

- Biological Safety Evaluation Plans (BSEP)

- Biological Safety Assessment Report (BSAR)

- Toxicology Risk Assessments (TRA)

- Quantitative Structure–Activity Relationship (QSAR)

Analytical Chemistry

Our team of chemists can help support your team with early exploratory research to full extractables & leachables programs. You can have confidence in the development and validation of your method.

- Extractables & Leachables

- Custom Chemical Characterization

- Method Development & Validation

- Material Characterization

- Formulation & API Development

- Opthalmic Product Development

- Studies for Contact Lense Products

- Pharmacokinetics & Pharmacodynamics

Consulting Team

James Eucher, DVM, DHSc, MS, MPH, DABT

Principal Toxicology Consultant

Biography

17+ years of professional experience including medical device, biocompatibility, clinical and other toxicology.

Experience in a range of settings including multiple CROs, industry, academia, government, and veterinary clinical practice.

Cheryl Marker, PHD, DABT

Toxicology Expert Consultant

Biography

Cheryl Marker, PhD, and a board-certified toxicologist (DABT), currently serves as a toxicology consultant at iuvo. Dr. Marker has more than 15 years of experience in the medical device and pharmaceutical industry as well as several years of clinical trial experience. Prior to joining iuvo, Cheryl was a Study Director at Contract Research Organizations (CROs) where she gained extensive experience overseeing a wide variety of study types including toxicology, pharmacology, biocompatibility, medical device, and interventional/surgical studies.

Cheryl also has expertise dealing with Good Laboratory Practices (GLP) requirements and ISO 10993 standards. Cheryl’s clinical trial experience includes contributing to investigational new drug (IND) applications, interacting with internal review boards (IRBs) and data safety monitoring boards (DSMBs), and managing/coordinating sites. Most recently, she managed a multi-site Phase I clinical trial. Cheryl earned her BS in Chemical Engineering with an emphasis in Biochemical Engineering from the University of Minnesota. She earned her PhD in Pharmacology with an emphasis in Neuroscience from the University of Minnesota Medical School. During Cheryl’s graduate studies, she focused on opioids, pain, and analgesia.

Liz Steiner

Sterilization

Biography

Strong expertise in EO adoption rationale and requalification; supports cross-functional study coordination

Jim Slota, MD, MSc

Toxicology Expert Consultant

Biography

Jim Slota, MD, MSc serves as a toxicology consultant at iuvo. Dr. Slota has over a decade of experience in the clinical medicine and medical device space. After graduating from medical school, Dr. Slota pursued clinical research opportunities at George Washington University where he served as Co-Investigator for several clinical trials.

Jim earned his MSc in Material Science and Engineering from North Carolina State University with a focus on bio- and nanomaterials. Prior to joining iuvo, Jim was a Biocompatibility Specialist at Applied Medical where he worked closely with Applied’s internal engineering team to develop biological evaluation plans and biocompatibility risk assessments for various medical device categories.

Jim brings expertise in development stage biomaterial selection, pre-clinical stage toxicological risk assessment, and biological testing analysis with an emphasis on material-based cytotoxicity challenges.

Connor Francek, BS, CPP

Packaging & Sterilization

Biography

Founder of Swish Packaging; former Sr. Packaging Engineer at Packaging Compliance Labs; MSU Packaging graduate; CPP-certified; PCT thru-hiker; BS in Packaging, Michigan State University